In the high-stakes world of heavy machinery, performance, efficiency, and reliability are not optional. Every component must contribute to uninterrupted operation from construction to mining and agricultural vehicles. One such critical component is the hydraulic valve. Among the most reliable brands in this category, Winner Hydraulic Valves has become synonymous with meeting the expectations of exceptional machinery performance and consistent delivery in even the most challenging conditions.

Introduction to Hydraulic Valves in Heavy Equipment

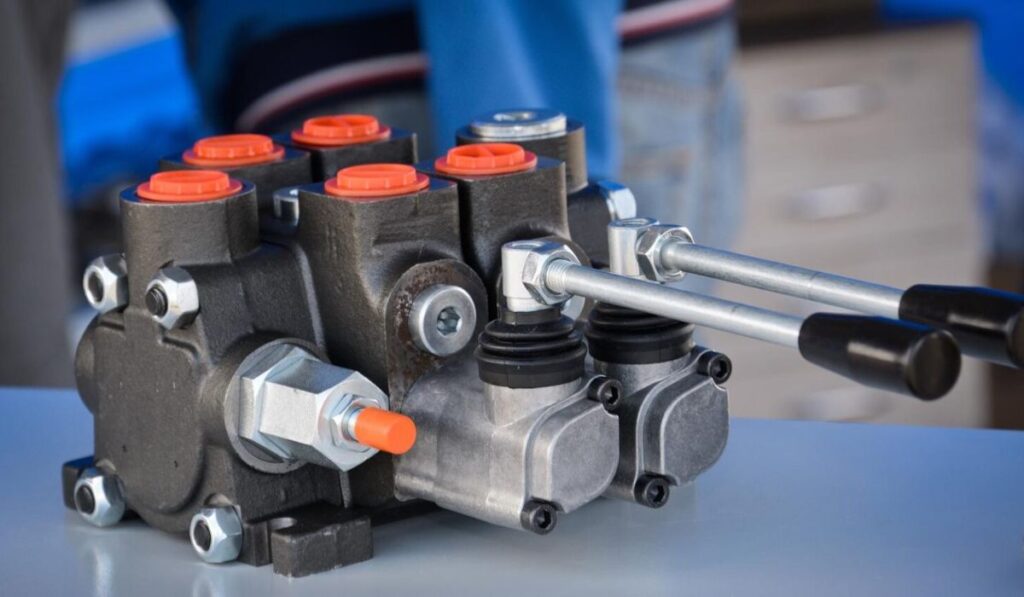

Hydraulic valves control the pressure and flow of hydraulic fluid in a system. The hydraulic valves control the direction of movement of actuators like motors or cylinders that, subsequently, move the various components of a machine. The role of these valves cannot be overemphasized—they lie at the center of a machine’s operation. Any malfunction or inefficiency in this device can cause downtime, rising maintenance costs, and loss of productivity.

The Application of Winner Hydraulic Valves

Winner Hydraulic valves are designed to withstand the intense requirements of heavy-duty applications. Renowned for their durability and accuracy, Winner Hydraulic valves deliver maximum fluid flow, minimize energy losses, and improve the general responsiveness of hydraulic systems. The design incorporates high-performance materials and advanced sealing technology, leading to longer service life and low maintenance.

Benefits in Actual Applications

Heavy equipment works under extreme conditions, ranging from high pressure to extreme temperatures. Winner Hydraulic valves are engineered to withstand such conditions. They offer better pressure control, critical for lifting heavy loads, digging through hard ground, or making precise movements with attachments.

The valves provide quick response times, ensuring operations are conducted smoothly and efficiently. This is particularly critical in construction and mining, where delays can result in substantial financial losses. Additionally, these valves help improve fuel efficiency by reducing energy wastage—an increasingly significant consideration in today’s environmentally friendly market.

Reliability and Durability

Another prominent feature that differentiates Winner Hydraulic valves is their longevity. Constructed from corrosion-resistant materials, these valves do not lose their performance even after extended moisture, dust, and hydraulic oil exposure. Their leak-free nature and pressure stability minimize the need for repairs, enabling machinery to operate longer with less downtime.

Operators and maintenance crews also enjoy the ease of replacement and installation, saving time on servicing and optimizing machine availability.

Compatibility and Versatility

Winner Hydraulic valves are compatible with numerous heavy machinery models. From excavators, bulldozers, loaders, and cranes to new and current systems, the Winner Hydraulic valves can be incorporated into them perfectly. Their extensive array of valve types—from directional control valves, pressure control valves, and flow control valves—makes it possible to have a suitable solution for each hydraulic application.

Conclusion

Heavy equipment requires parts that are as resilient and reliable as the conditions in which they operate. Winner Hydraulic valves step up to the task by providing outstanding performance, efficiency, and reliability. Their capacity to improve system responsiveness, save energy, and minimize maintenance makes them a preferred option for operators who want to maximize their machines. As the core of hydraulic systems, these valves are key in driving industry productivity, one trustworthy operation at a time.